In recent years, emissions reduction and forest protection in supply chains have become top of the boardroom agenda. Consumer goods companies don’t need to be convinced about the relevance of sustainability anymore, they need to know how to achieve their sustainability commitments. First and foremost, they need to ensure the processes that produce their products don’t cause deforestation. That means working with suppliers and traders that aren’t causing deforestation.

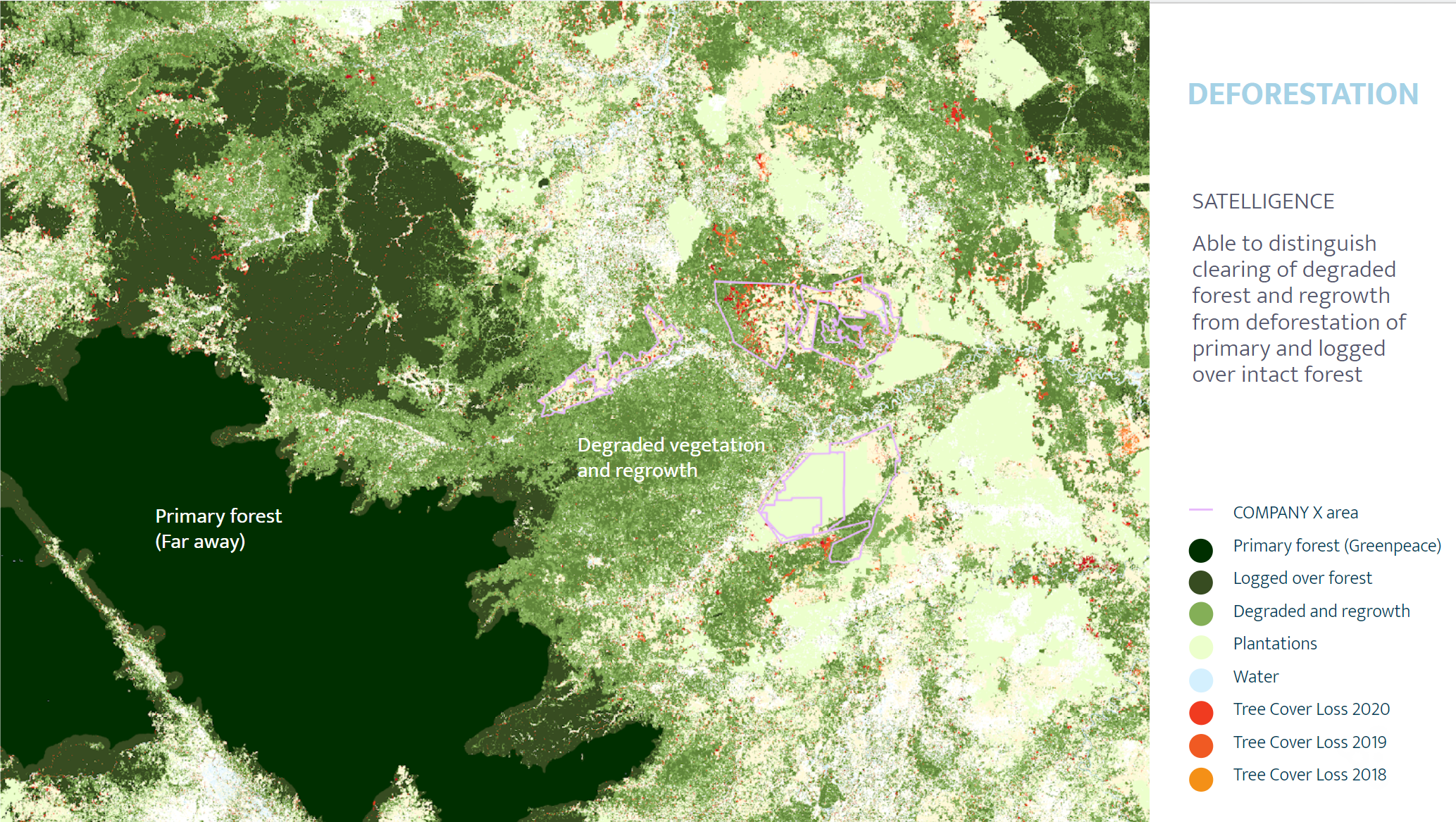

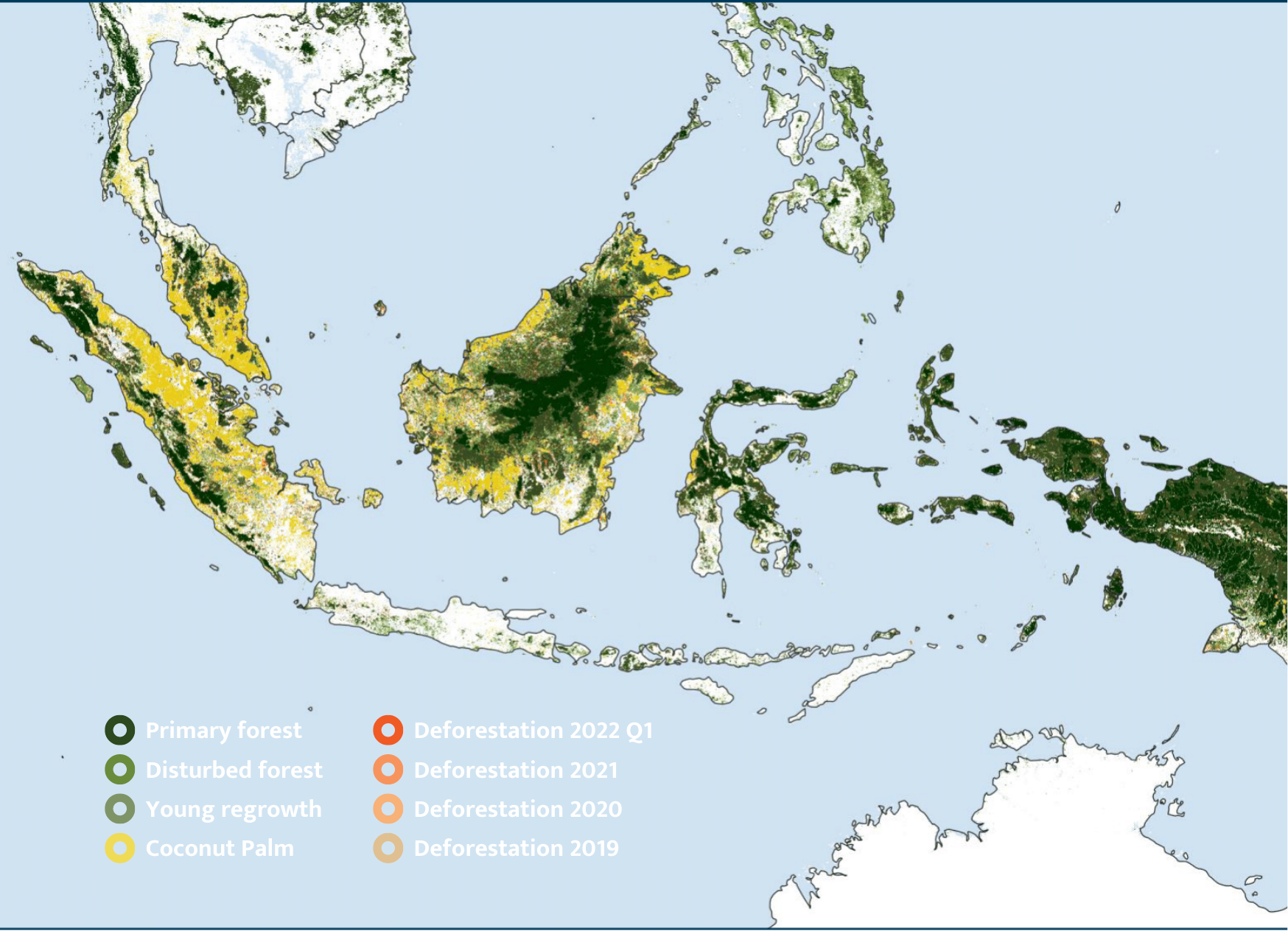

Deforestation is the leading cause of emissions in supply chains and many commodities, like palm oil, have been publicly associated with deforestation for some time. Satellite monitoring, combined with expert analysis and supply chain information, can provide unprecedented levels of traceability for businesses looking to make sure their products are sustainable, from tree to shelf.

Scaling Supply Chain Sustainability with Satellites

Satelligence collects all of the image data from orbiting satellites. Every day, new satellite information is fed into the system, and the archives of that satellite data cover the entire world. The suppliers and traders that sell to consumer goods companies can potentially source their commodities from thousands of mills, which are connected to hundreds of thousands of plantations. Ground level auditing can’t scale enough to identify or instigate behaviour change among the “bad actors” using non-sustainable practices on their concessions. In order to get consistent visibility across such large areas, companies need to use satellite monitoring.

Companies can only engage with and leverage suppliers into changing their practices if they actually know who owns the concessions and if they can conclusively prove that deforestation has occurred on their farms. Gathering and updating supply chain information is a large part of Satelligence’s work. For palm oil alone, Satelligence monitors 65,000 farms, and over 2,000 mills.

Satelligence’s satellites are capable of monitoring deforestation to 10m2 of detail, which can lead to a deluge of data. Companies don’t have time to verify 100,000 deforestation alerts. Not all tree loss is deforestation, nor can it always be traced back to company activities. Timber companies, forest fires, and infrastructure encroachment can all contribute to tree loss within a concession.

Each commodity and region type needs its own specialised algorithm to detect land cover changes accurately, ensuring companies don’t waste time and money on false positives that can damage their credibility. That’s why Satelligence has tailored their analysis with an ISAE-3000 Type 1 Certified algorithm that uses machine learning to constantly improve its ability to detect land-cover changes and other environmental risks accurately.

The data is then curated for client use, so they can engage, evidence in hand, with their suppliers, traders, or individual farms about deforestation. Satelligence can provide information about deforestation and sustainability performance at the supplier level, allowing companies to compare supplier performance and revise their sourcing portfolios as necessary.

Driving Behaviour Change and Best Practices

The EU Regulation on Deforestation-Free Products is contributing to a rise in the use of satellites to fight deforestation as the EU due diligence statement requires companies to collect geo-coordinates of the farms and plantations where their commodities are grown. If they cannot, they won’t be able to trade in the EU. The EU Commission recommends satellite data as an effective tool to achieve supply chain traceability in Article 9 of the Regulation’s draft.

In order to verify their supply chain as deforestation free, companies need to know where their ingredients were grown. This involves carrying out a supply chain mapping exercise. Once the supply chain is mapped out, companies can see whether suppliers are implementing sustainable practices or working towards deforestation reduction targets. Another benefit is that companies can identify and engage with bad actors before NGOs turn up on their doorstep with reputation-threatening reports. Once suppliers know someone is watching from the sky, they’re often quick to change their behaviour.

Looking Ahead: Ensuring Inclusive Sustainability

The field’s nascency means that working on these solutions can feel like building a plane while flying. However, ambitious early adopters, such as those in the palm oil sector, are starting to reap the rewards. If the palm oil sector’s recent achievements tell us anything, it’s that multi-stakeholder cooperation and enthusiastic adoption of satellite monitoring tech bring results in the fight against deforestation. Palm oil’s successes are moving public opinion in favor of the much-maligned sector.

Consumer goods companies should look to use suppliers that are already importing into the EU, with verifiable processes in place. On the other hand, smallholders are harder to trace when compared with larger farms. The adoption of new technology runs the risk of creating a two-tier market, where smallholder farmers are excluded as they are not equipped to cope with meeting the demands of the EU regulation.

Companies can carry out stakeholder engagement activities and work through partnerships to help smallholders put the right systems in place, and get the right land titles and ownership information. For companies to prove their deforestation-free claims, they need to tidy up and professionalize the whole supply chain in its entirety.

The technology is capable of monitoring at a farm-by-farm level, including smallholders. Stakeholder engagement is the biggest challenge. Detailed supply chain mapping exercises at the smallholder level are often painstaking and can run the risk of excluding indigenous and smallholder farmers.

One thing that isn’t a challenge is cost. The relative cost for monitoring sustainability is often less than a cent on a chocolate bar or a packet of margarine. However, for some procurement managers, that could be considered a lot of money. When considering the significant progress towards mainstreaming deforestation-free supply chains in certain commodity sectors, and the incoming regulations that will make meeting one’s sustainability commitments the new cost of doing business, it’s money well spent.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.