Many of our daily consumer goods are in the news daily. Soy production is said to be driving tropical deforestation, palm oil expansion to be endangering the livelihoods of orangutans and beef cattle is the number one cause of forest carbon loss globally. The latest perpetrator? Natural Rubber. In this story we tell you all about how sustainable natural rubber: what has already been done and what needs to be done to ensure a global sustainable supply chain?

Coming from rubber trees and extracted by making incisions into the bark and collecting the gooey tree sap into buckets, rubber tree plantations comprise an estimated 12 million hectares globally. In Southeast Asia, where an approximate 97% of the world’s rubber is being produced, rubber expansion is posing a large deforestation and biodiversity treat. In addition, rubber production is linked to environmental problems like carbon emissions and water contamination. The question we need to answer now is: How to make the best use out of existing plantations, while protecting the environment and biodiversity?

Sustainable rubber standards

The good news is that many tire companies – who buy about 70% of the global natural rubber reserves – and shoe giants like Converse and Timberland, have made steps towards a sustainable rubber supply chain. The October 2018 launch of the independent Global Platform for Sustainable Natural Rubber (GPSNR) – with members like BMW group and tire giants Michelin, Continental and Bridgestone – indicates the sector’s willingness to make socio-economic and environmental improvements.

The Forest Stewardship Council (FSC) has certified over 350.000 hectares of rubber with a standard that promises to confirm the rubber isn’t linked to forest degradation or deforestation, and demonstrate the producer has implemented best management practices.While these initiatives towards a more sustainable natural rubber supply chain are very encouraging, measurable and visible information for tracking progress is not yet available.

3 ways to track progress

Satellite data help track progress towards a sustainable natural rubber supply chain, in three ways:

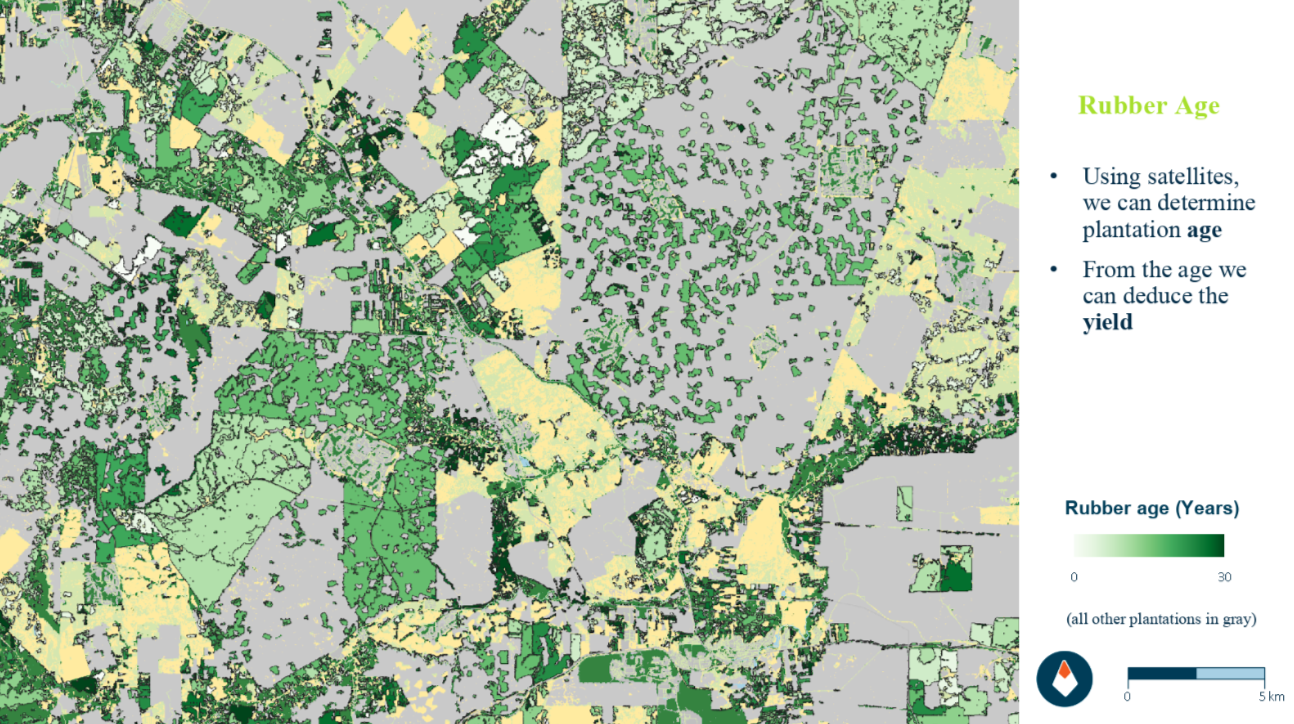

1. Satellite data can help us to identify where plantations are located and make the most out of existing plantations. This helps to improve logistics processes involving thousands of smallholders. Moreover, when the trees age between 20 – 25 years of age, rubber production starts to drop. Spotting plantations that reach this age from space can help replanting initiatives allocate resources to make the most out of planted area so now new land needs to be cleared.

2. Satellite data can help monitor deforestation and protect biodiversity. To know where and when deforestation is happening in the supply chain, to take action to protect the forest. Alerts showcase in real-time those suppliers who are not involved in deforestation and other environmental damage, but produce responsibly and re-green the planet.

In this GIF, you can see forest clearing and conversion to rubber plantations in Peninsular Malaysia between 2015 and 2017.

3. Satellite data can help early detection of pests. Dropping yields observed by satellite can signal pests & disease. For many smallholder farmers that depend on their rubber plantation for their livelihood, it is essential to be alerted of any disease risk on time.

Towards a better future

While the recent developments in sustainable natural rubber are very promising, there is still a long way to go to set a worldwide standard for companies to adhere to certification standards and setting up a system to track this. Next up, the challenge will be to incorporate the latest technologies to help advance the production of sustainable rubber.

Contact us

If you want further insights into demonstrating sustainable natural rubber production, plan a 30 minute call with us!